Site translations now available in Spanish and German

About Hydro

About Hydro Systems

Hydro™, a brand of PSG®, a Dover company, is a world leader in delivering chemical dispensing, dosing, and injection solutions, including equipment, software and services. With strategic partnerships, innovative solutions and more than 50 years of experience, Hydro is committed to enriching the lives of its customers by creating a cleaner, more sustainable world. Its products serve numerous markets including facility cleaning, laundry, kitchen, animal health, car wash, horticulture, laundromat, and industrial markets. Hydro ensures dosing is always accurate, safe and cost effective, helping customers clean with confidence.

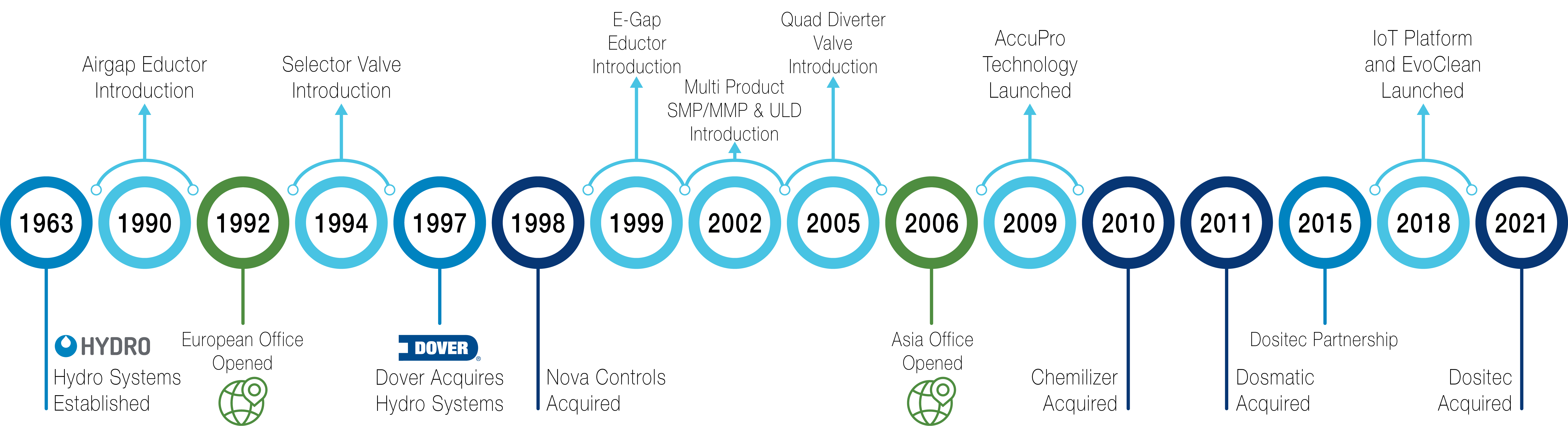

Hydro Systems was established in 1963 in Cincinnati, Ohio, USA. Our origins were in manufacturing pressure washers. In 1983 we decided to focus our efforts in the relatively new chemical management space and have since become a world leading manufacturer of chemical dilution, dosing, and injection systems. These systems are traditionally found in facility cleaning, laundry, kitchen, animal health, car wash, horticulture, laundromat, and industrial markets. Hydro’s innovation-driven technologies include venturi dispensers, water-driven pumps, peristaltic pumps, central dosing systems, and web/mobile applications and controllers.

In addition to our North American corporate office, we have manufacturing and distribution facilities in China and Germany.

Here, briefly, are the benefits of using using chemical dispensing, dosing, and injection equipment:

- Environmental Friendliness: Automatic dilution helps prevent chemical “over-doses” from being dumped into sanitary sewers, or other places where they can harm water supplies. Also, this equipment makes using concentrated chemicals easier, and shipping concentrates uses less fossil fuel than shipping enough ready-to-use products to accomplish the same amount of work. There’s also a lot less solid waste packaging to dispose of, too.

- Safer work environments: By automatically mixing concentrates with water, workers don’t have to lift heavy containers as frequently, reducing back strain, and their exposure to the concentrated chemicals is reduced as well. Properly diluted chemicals can also help to reduce “slip-fall” accidents by leaving surfaces clean without depositing a slippery residue.

- Increased productivity: Workers can spend their time cleaning, not measuring and mixing the solutions they need to perform their work. Training time is also shortened since workers don’t have to learn to mix the products.

- Cleaner work areas: Consistent dilution of cleaners to the manufacturer’s specifications helps concentrates work as they are designed to work. Overly rich mixtures can leave residues or even damage the cleaned surface. Overly weak mixtures can leave the “cleaned” surface unsanitary.

Regulatory acceptance: see our Regulatory Info page for our list of approvals.

Watch our Quality Video

PSG

Cincinnati, OH 45244

Cincinnati, OH 45244

For new product, event and industry updates:

By entering your email you agree to receive marketing messages from PSG Hydro. You may unsubscribe at any time.

Hydro Resources

Hydro Resources

© 2026 PSG All Rights Reserved | A Dover Company | Privacy Policy | Cookies | Terms of Use