Case Study: Queen City Laundry Levels Up with Hydro™ Perfect Pour™

Introduction

Dave Menz wasn’t a household name when he bought his first Queen City Laundry laundromat in 2010. The small, self-serve facility located in Ohio was meant to be a side business to generate supplemental income. When he made the purchase, he worked as a full-time lineman, servicing phone lines. “When I first got in the industry, I had no resources,” Menz said. “I had a full-time job and then did the laundromat on nights and weekends.”

His foray into this new world proved challenging, but Menz sought to turn around his investment. He researched how successful laundromats operated, the technology and services available, and strategies to excel.

It started with changing the business model to turn his first laundromat into a profitable operation. He then “rinsed and repeated” that business model in two additional locations. Menz continued to gain traction, adding improved technology and wash, dry and fold services. A fourth location followed, which added delivery and pickup options for his customers.

Menz’s reputation grew exponentially, with Queen City Laundry gaining popularity across the state. His success earned him the nickname Laundromat Millionaire™. This alias allowed Menz to create a successful podcast for the laundromat industry and become a thought leader who shares his knowledge and methods through personal coaching. As many have seen, Menz built his legacy through innovation, strategic approaches, and focusing heavily on improving the customer experience.

“There was a journey in there for sure that is not typical,” he said. “Most people are not willing to do the things we were willing to do. I evolved and reached the top of the industry.”

So, how does a successful entrepreneur turned industry influencer continue evolving? Menz said he always looks to improve every aspect of his business. This multi-faceted approach includes his customer experience and bottom line, which he achieves by always searching for the best equipment and services.

During a networking event at the Excellence in Laundry conference in 2023, Menz stumbled upon an innovative breakthrough. Engaging in a fateful conversation with a sales representative from Hydro™, a world leader in delivering chemical dispensing, dosing and injection solutions, he discovered the company’s latest innovation – the Perfect Pour™ system – now a staple at his Amelia, Ohio, laundromat.

Nearly a year after Perfect Pour was implemented, Menz’s expenditures on laundry detergent have dropped significantly, totaling to an estimated 75% savings. The service side has seen an uptick in efficiency, and a reduction in waste, equating to a total labor savings of about 4%. The short window has convinced Menz that the Perfect Pour system is a “revolutionary” product that can change the efficiency, effectiveness, and customer experience of laundromats nationwide.

The Perfect Pour Details

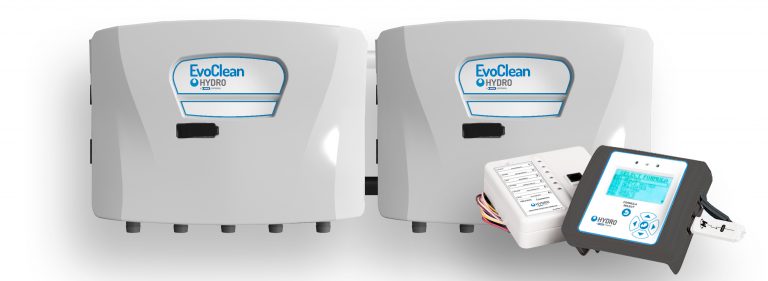

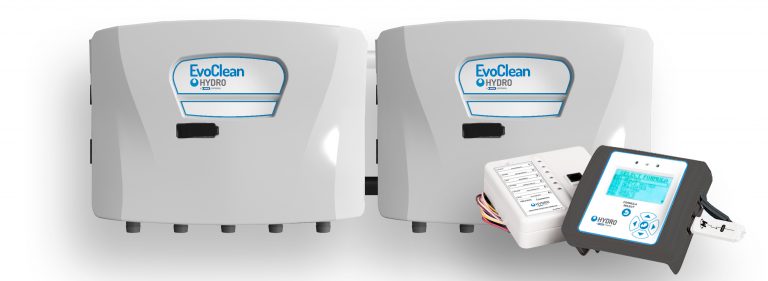

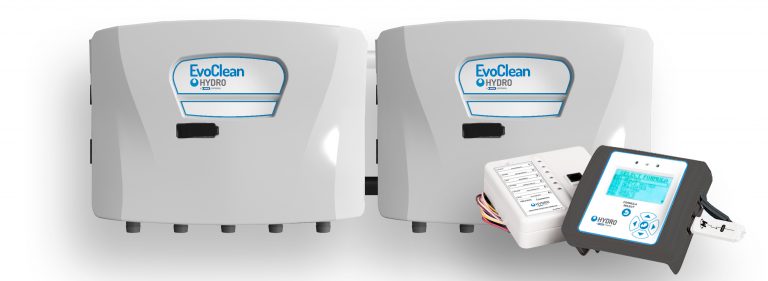

Hydro Perfect Pour is a direct injection system designed to provide customers with convenient detergent options and improve a laundromat’s bottom line. Customers only need to bring their laundry with them and select their preferred detergent at the push of a button.

The system features a central dosing panel, several distributor valves for water and chemicals, a flowmeter for detecting leaks and ensuring proper flow, delivery lines, and 55-gallon barrels containing chemicals. The system can distribute up to 10 chemicals per line per washer and connect up to 100 washers, as opposed to competitive dosing systems that require separate tubing and delivery systems for each chemical used (per washer).

The central dosing panel serves as the brain of the Perfect Pour system, signaling to the distributor valves and delivery lines when and how much chemical product to send to the washer. The panel scales the water and chemicals dispensed based on the weight of the load, or the capacity of the machine, depending on the laundromat owner’s preference. The entire system is typically installed in a private location in the facility, out of sight of the customers. Depending on the laundromat owner’s preference or floor plan, the distributor lines can run underground or overhead. Perfect Pour can be installed in new builds or retrofitted into existing operations.

The system can also be paired with Hydro Connect to give users real-time alerts and analytics. Hydro Connect is a cloud-based Internet of Things (IoT) platform that offers chemical providers and end users increased visibility into their operations. It is built on the Microsoft Azure platform and utilizes data generated from Hydro Central Dosing Systems. Users can access advanced reporter statistics through Hydro Connect, including the number of chemicals consumed and loads run.

Menz realized early on that Perfect Pour had more versatility than traditional direct injection systems. The drawback of the latter systems came from their limitations on detergent selection. Customers typically only had one detergent choice. If they didn’t like it, they couldn’t bring their own. With Perfect Pour, the customers can use the system or opt for a manual experience. But if they use the system, they only have to bring one thing with them – their laundry.

“The key with installing Perfect Pour was further improving the customer experience,” Menz said. “This is a different level of direct injection. Perfect Pour is revolutionary. It truly is a no guess, no mess, no stress operation.”

A Better Customer Experience

After several discussions with Hydro, the company installed four Perfect Pour systems at the Amelia laundromat. The systems went live in April and are available on all of the laundromat’s 38 washers.

Several months later, Menz said Perfect Pour is a popular feature for his customers. Many customers enjoy not having to worry about bringing laundry detergent and love the convenience of only bringing their dirty laundry, placing it in a washer and pressing a button.

Many customers appreciate the convienence of automated dispensing in case they forget their detergent. But if they want to use their own, they are not dependent on the system, which is a critical factor in Menz’s decision to add Perfect Pour.

“Our customers are loving it,” he said. “The key to the whole thing is it’s not a take it or leave it proposition. They can use their detergent or use the system. My customers appreciate having a choice. To utilize Perfect Pour technology, all they have to do is hit a button. That creates a memorable, world-class customer experience. In fact, all aspects of my business have improved because of Perfect Pour. The system has helped us reach the next level.”

Financial Benefits

From an operational standpoint, the Perfect Pour system provides several financial benefits. Menz no longer needs to purchase detergent in bulk from wholesale stores like Sam’s Club and Costco. While cheaper than buying those products from retail stores, the costs still add up. Instead, Menz can now buy his detergent in 55-gallon drums at a much more affordable rate than retail and wholesale stores, cutting his former detergent expenses by 75%.

In turn, Menz can enjoy those cost savings while selling that detergent via the Perfect Pour system for a markup in the $1 to $4 range per cycle, depending on the size of the washer. As his customers opt-in to use this new system, those markups translate into profits, especially if each product, such as detergent and fabric softener, is selected and paid for.

Additionally, having new technology in his laundromat will attract new customers, possibly from competitors. As he’s seen with his current base, the convenience of Perfect Pour has already gained favor.

“People can come in and not bring soap. They don’t have to worry about pouring it or measuring it,” Menz said. “There’s a certain segment of our market that we have this next level of service, and I’m banking on that driving those customers away from competing stores to our own.” Currently, based on machine capabilities Menz’s Amelia laundromat only has one detergent option, but he plans to increase that to four options in the coming months, giving his Perfect Pour customers an abundance of automated detergent selections. Within two years, Menz anticipates he’ll have his total return on investment with the Perfect Pour system.

“What we have now is really good, and it’s only going to get better,” he said. “I’m not aware of any other laundromats out there doing everything we’re doing to elevate the customer experience.”

Better Service Efficency

Benefits from the Perfect Pour system can be seen beyond customers using it within the self-service laundry area. The Amelia laundromat’s wash, dry and fold operation has seen a 2-3% efficiency increase. While those don’t seem like high percentages, Menz explains that he already had high standards for his wash, dry and fold team, and Perfect Pour only made them better.

The wash, dry and fold team has seen improved efficiency in their processes from no longer manually accessing and pouring detergent and softeners before starting the washers. The staff only has to push a button. With thousands of pounds of laundry processed per night, removing this manual step saves his staff time. Perfect Pour also eliminates the possibility of spills and the time it takes to measure the detergent.

“Whatever spills and messes they make, they have to clean it up,” Menz said. “Those things slow them down. Their job got easier with this tool. I didn’t realize how it would impact them. They think it’s the best thing ever.”

Conclusion

Much has changed for Menz since his first laundromat purchase. He’s established a successful laundromat business that continues to evolve while pushing the boundaries of what is possible for a laundromat to thrive. His track record of innovation now continues with Perfect Pour, a system that has him looking ahead to an even brighter future.

“Perfect Pour has already helped us take our business to the next level,” Menz said. “This system has the potential to not only make us even more successful but completely revolutionize our industry.”

About the Author

Patrick Kelley is the GTM Manager, Industry Segments, for Hydro™ and can be reached at patrick.kelley@psgdover.com. Hydro, a brand of PSG®, a Dover company, is a world leader in delivering chemical dispensing, dosing and injection solutions, including equipment, software and services. With strategic partnerships, innovative solutions and more than 50 years of experience, Hydro is committed to enriching the lives of its customers by creating a cleaner, more sustainable world. Its products serve numerous markets, including facility cleaning, laundry, kitchen, animal health, car wash, horticulture, laundromat and industrial markets. Hydro ensures dosing is always accurate, safe and cost-effective, helping customers clean with confidence. To learn more about Hydro, please visit hydrosystemsco.com.

Customer Service and Technical Support

Call 1-800-543-7184 Monday-Friday 8am - 5pm EST